Sustainable processing: the Wauters Group’s newest investments

Hot stamping, embossing, varnishing, laminating… These refined finishes are an integral part of luxury packaging.

As experts in hot stamping and high-added-value processing, Wauters has always invested in cutting-edge equipment. As well as performance and visual renderings, significant environmental factors – particularly ones that will lead to the elimination of all plastic from packaging – are in play. With an eye on upcoming challenges, the Wauters Group is preparing itself, equipping itself, and investing in order to provide new eco-friendly packaging options without compromising on perceived value.

B.Pack – Wauters’ Burgundy location – has therefore been fitted with 2 new pieces of equipment: a cold stamping unit paired with an offset printer, and a plastic-free metallising transfer unit.

Cold stamping: a new area of expertise comes to B.Pack

Following the Paris location in 2021, it’s our Burgundy location’s turn to be equipped with a new Heidelberg offset printing machine and a cold stamping unit.

This process – a new cornerstone in the House’s gilding expertise – complements hot stamping while providing several benefits:

- a streamlined process which doesn’t require a gilding iron or calibration on a new machine

- unrestricted design options thanks to registration quality, which makes layering finishes easier, enables finer dots for limitless decoration details, and allows for an infinite colour palette.

- an eco-friendly process that cuts down material and energy consumption by avoiding the use of gilding iron tools while recycling the PET film spools.

Plastic-free metallisation transfer

B.Pack has also just been equipped with a new metallisation transfer unit. This new lamination technique takes place before printing. It consists of applying an all-over metallic effect on a case. These laminations are made of a plastic film glued on with a metallisation layer which, up until now, was applied to packaging at the same time as the metal effect. Nowadays, by using a new, more eco-friendly unit, only the metallisation layer gets applied: the plastic film gets removed, retrieved, and recycled.

Our location in the greater Paris region will also receive this unit in the coming months.

At both our production locations, we will therefore be able to achieve metallic effects without plastic, whether it be in cold lamination or metallisation transfer (hot stamping is already plastic-free).

Between hot and cold stamping, metallisation transfer, and offset printing, Wauters and B.Pack are both equipping themselves in tandem to offer you the most innovative, efficient, and eco-friendly techniques for perfected packaging.

The Wauters and B.Pack teams

More on Wauters and B.Pack

Martell x Wauters: French expertise at its best

As an icon of French luxury and expertise, Maison Martell needs no introduction. Since its foundation 300 years ago, it has made a name for itself as an authority on cognac.

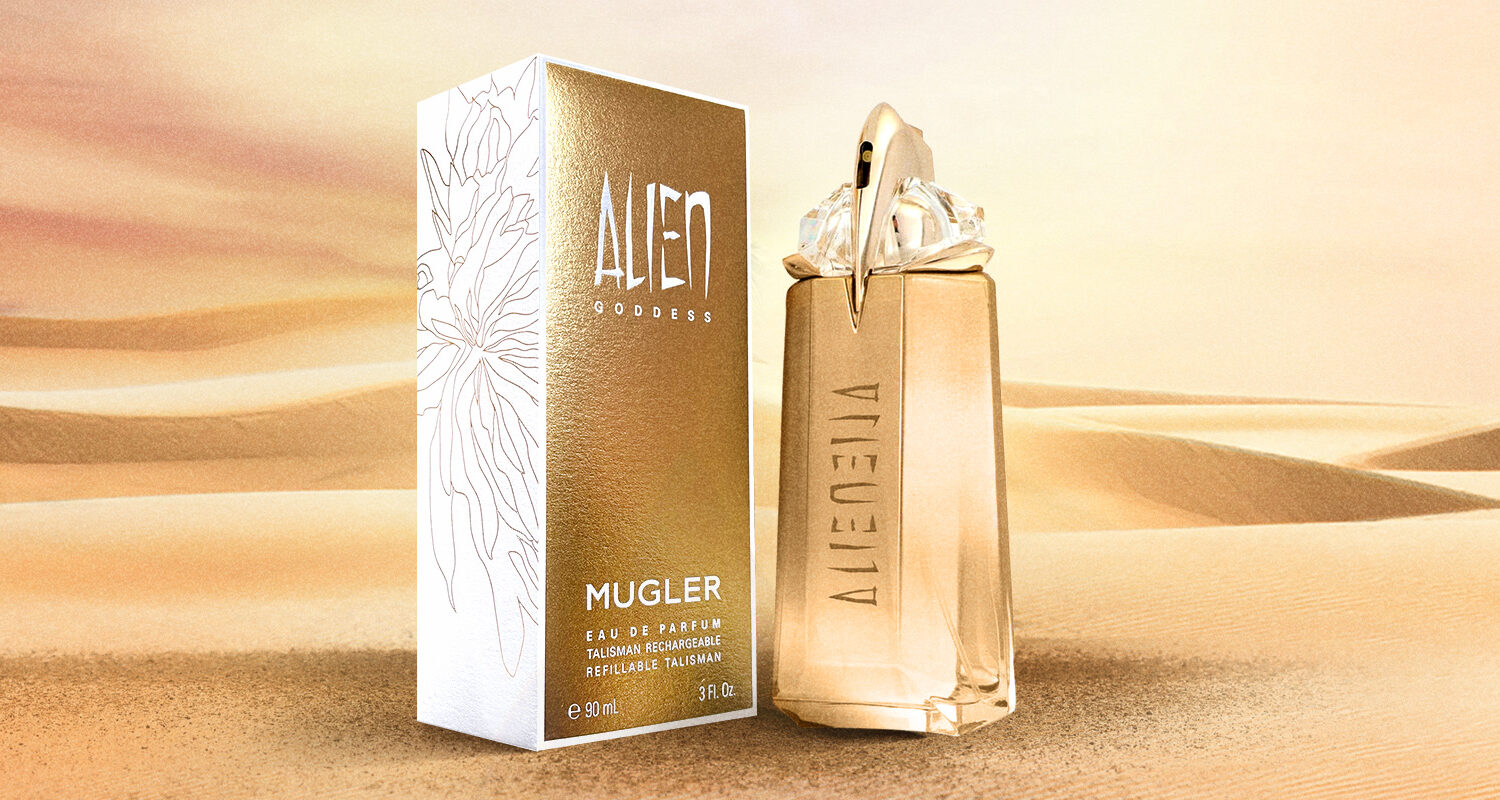

Wauters x Alien Goddess: solar down to the packaging

The solar, divine Alien Goddess, Mugler’s flagship product, has become an essential eau de parfum in the world of perfumery. In keeping with the brand, Wauters has mobilised all its know-how to adorn the box in gold and sunlight.

A step forward for the environment: CTP goes green.

Aware of the impact of our industry on the environment, we have been working to reduce our carbon footprint for many years now.

The EcoVadis Rating having awarded our Paris site Platinum level and our Burgundy site Gold level, we are constantly improving each stage of our production process.