A step forward for the environment: CTP goes green.

Aware of the impact of our industry on the environment, we have been working to reduce our carbon footprint for many years now.

The EcoVadis Rating having awarded our Paris site Platinum level and our Burgundy site Gold level, we are constantly improving each stage of our production process.

Indeed, we are investing in new machines, new processes and increasingly ecological tools such as ClimateCalc which allows us to calculate the carbon footprint of the boxes. We are also using biosourced inks, cold stamping which makes PET-free metal plating possible etc.

CTP: Computer To Plate and the printing plate

The offset printing process requires a large amount of water. In particular during the pre-press stage, when the offset plates required for the layout of each colour during printing are created by the CTP. Well, up to now, this indispensable tool has consumed huge amounts of water and chemicals.

Ecology and performance

For several years now, CTPs have gradually improved their ecological performance. In compliance with the Wauters group commitments, we have come up with a new type of product: plates without chemical development.

Considerable water saving:

To date, the plates were developed through a bath composed of a developing agent and a fixing agent, as well as a huge quantity of water. Thanks to this new process, the preliminary bath is no longer necessary. The photosensitive layer is revealed directly on the offset printing press with the wetting agent and the non-printing part stays on the slip sheets.

Furthermore, the cleaning is now performed with gum arabic of 100% natural origin, an exudate of elaborated sap.

This new investment allows us to save up to 120m3 of water annually.

Increased performance:

These new products lead to a reduction in time of use and costs thanks to the lower consumption of water and chemicals.

They also ensure greater comfort in the workplace and more safety for our teams as they limit the exposure of employees to hazardous chemicals.

Anticipation, foresight, implementation: we are working hard to offer you increasingly eco-friendly and higher-performance solutions, as well as provide you with an environmentally responsible service for your projects.

The Wauters and B.Pack teams

More on Wauters and B.Pack

Sustainable processing: the Wauters Group’s newest investments

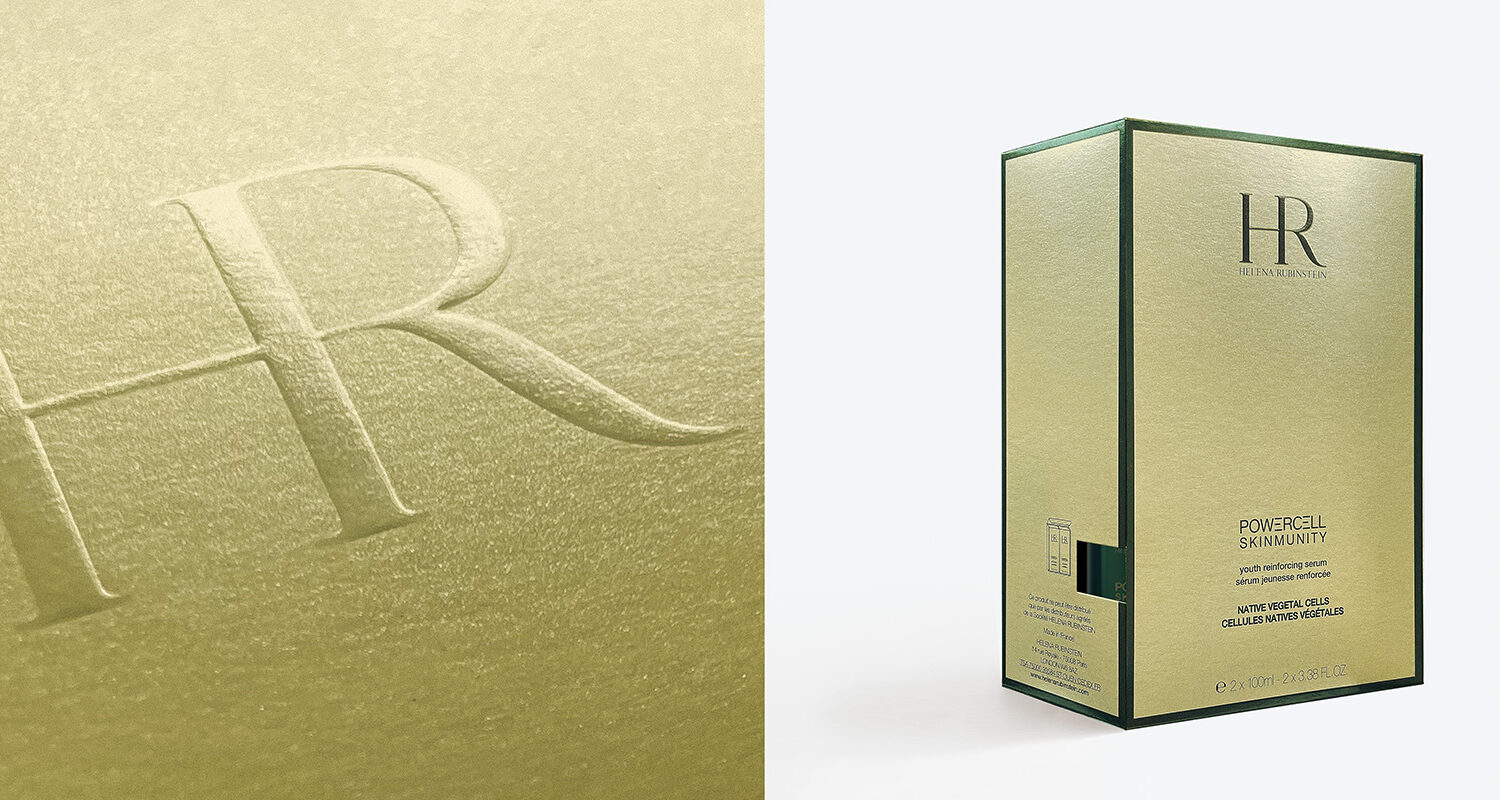

Hot stamping, embossing, varnishing, laminating… These refined finishes are an integral part of luxury packaging.

As experts in hot stamping and high-added-value processing, Wauters has always invested in cutting-edge equipment.

Martell x Wauters: French expertise at its best

As an icon of French luxury and expertise, Maison Martell needs no introduction. Since its foundation 300 years ago, it has made a name for itself as an authority on cognac.

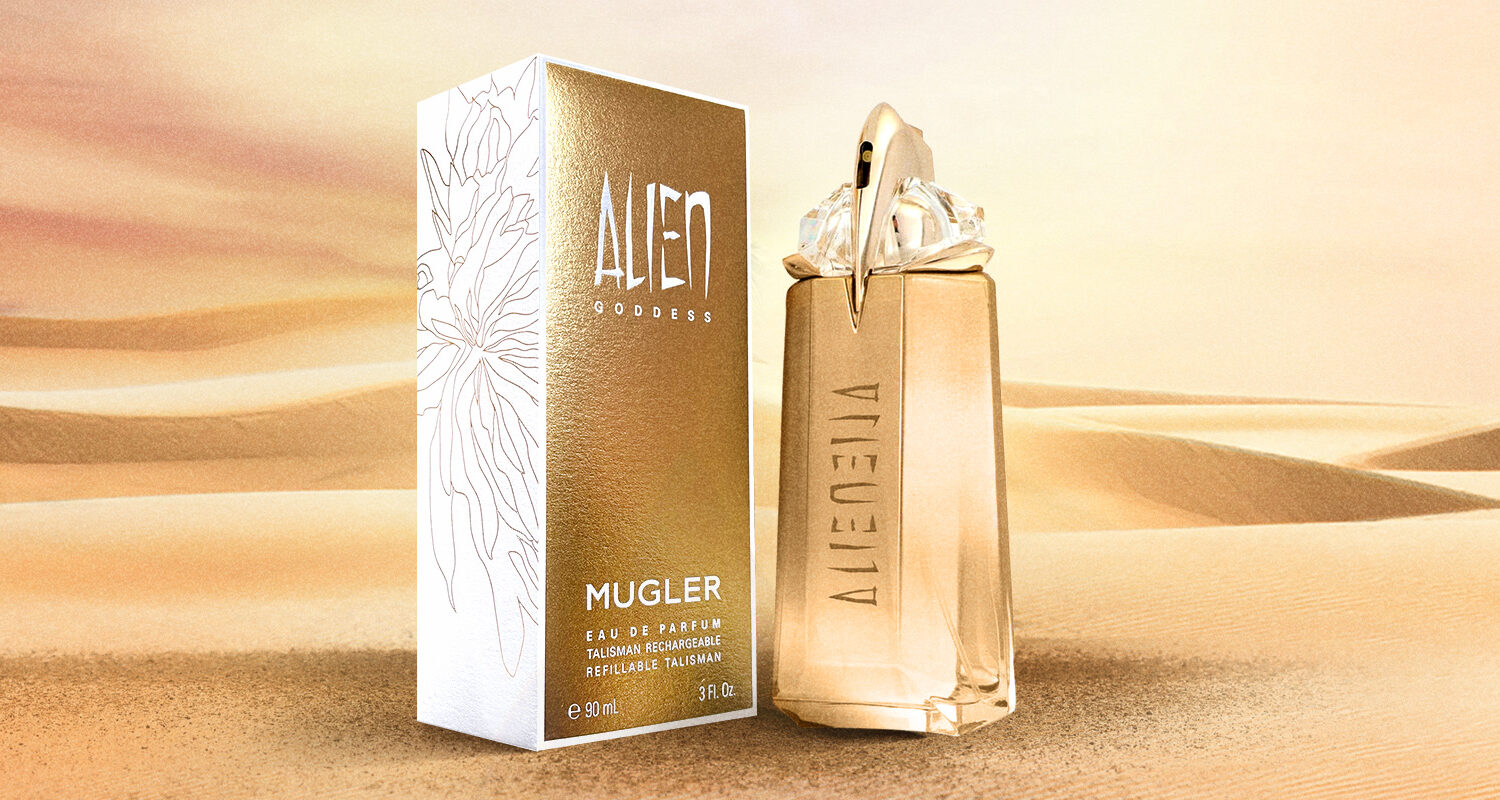

Wauters x Alien Goddess: solar down to the packaging

The solar, divine Alien Goddess, Mugler’s flagship product, has become an essential eau de parfum in the world of perfumery. In keeping with the brand, Wauters has mobilised all its know-how to adorn the box in gold and sunlight.