Cold foil stamping by Wauters

Wauters has been “packaging goldsmiths”… since 1909 and gilding has always been at the heart of the company’s history. Today, this hallmark finds its expression in a new investment and novel technical and innovative know-how, which open up fresh perspectives for packaging.

From gold foil to industrial innovation

Charles Wauters originally set up a leather gilding workshop in the Marais district of Paris for bookbinding, book covers, leather desk blotters, etc. He invented his tools, developed FIXOR (a type of glair for binding gold foil, which is still marketed by Rougier & Plé), and equipment that is now the mainstay of today’s gilder’s trade.

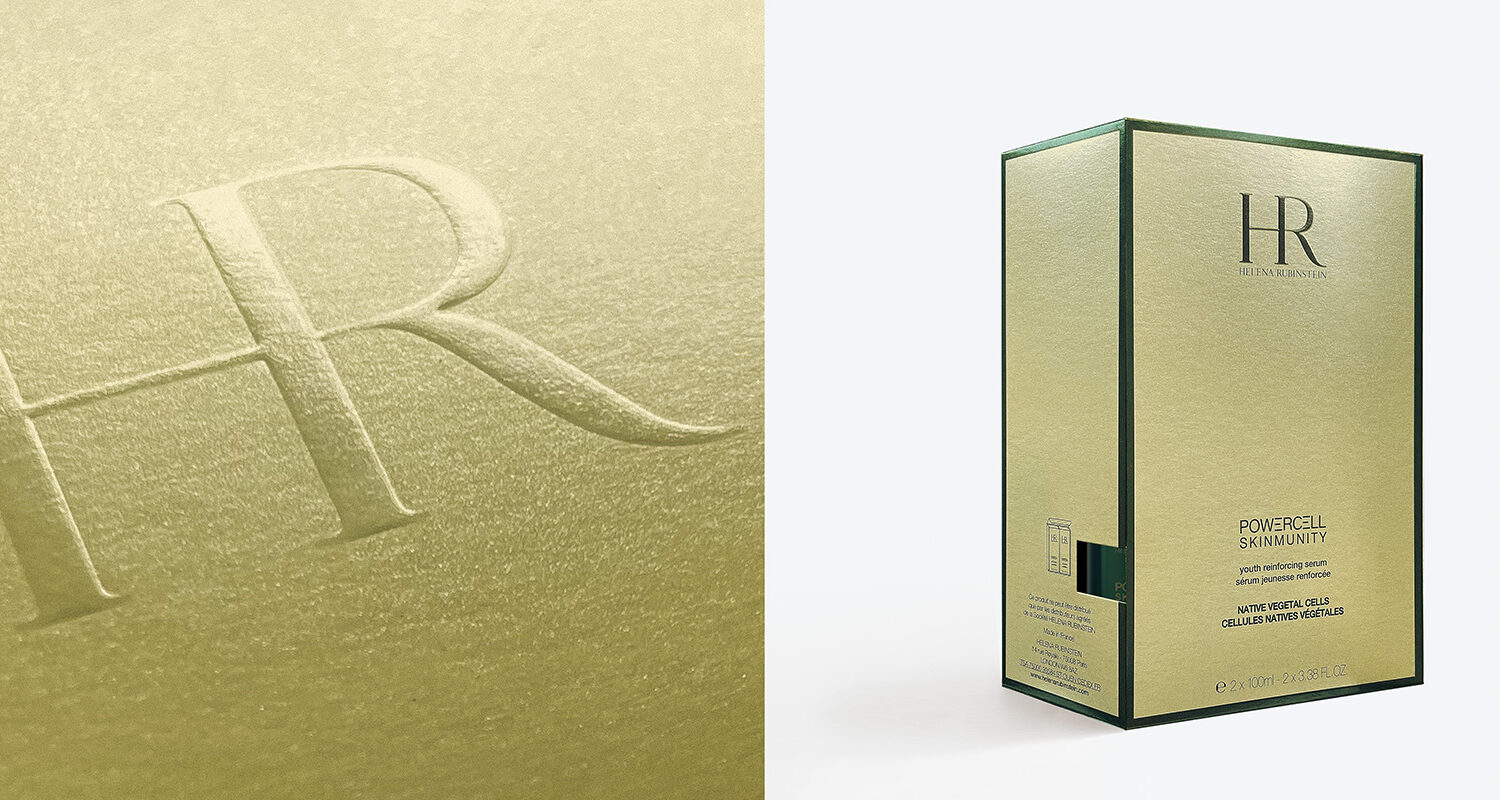

As gilding experts, we at Wauters have adapted and refined our know-how of leather to cardboard. Today, we work with the most prestigious brands in the Perfume, Cosmetics and Spirits industries to produce boxes with a high added value.

Year after year, we equip ourselves with the most precise and specific technologies, such as hot stamping in cylinders connected to an embossing unit with a one-of-a-kind machine, developed in partnership with Steuer and which provides unparalleled precision for hot stamping on large solid areas.

Naturally, Wauters is now developing their cold stamping offer.

A cutting-edge offset press… for cold gilding

Last year, Eric and Thierry Wauters (4th generation in the company) decided to invest in and equip the Bourguignon B.Pack site with a new offset press.

The Villebon-sur-Yvette site is next in line this year. It will be equipped with the brand-new Heidelberg CX 104 machine, which was quite recently revealed exclusively at the China Print trade fair. Wauters will be the first company to take advantage of this new, more efficient, ergonomic generation of offset presses with a unique intuitive control panel which makes it possible to increase the printing format even more with a sheet size of 720 x 1,040 mm.

This equipment is currently complemented by a Vinfoil Optima cold stamping (or cold lamination) unit. A new phase in the company’s “gilding” know-how is developing and, true to Wauters’ high standards, is moving towards technological sophistication that offers many possibilities.

Cold stamping by Wauters

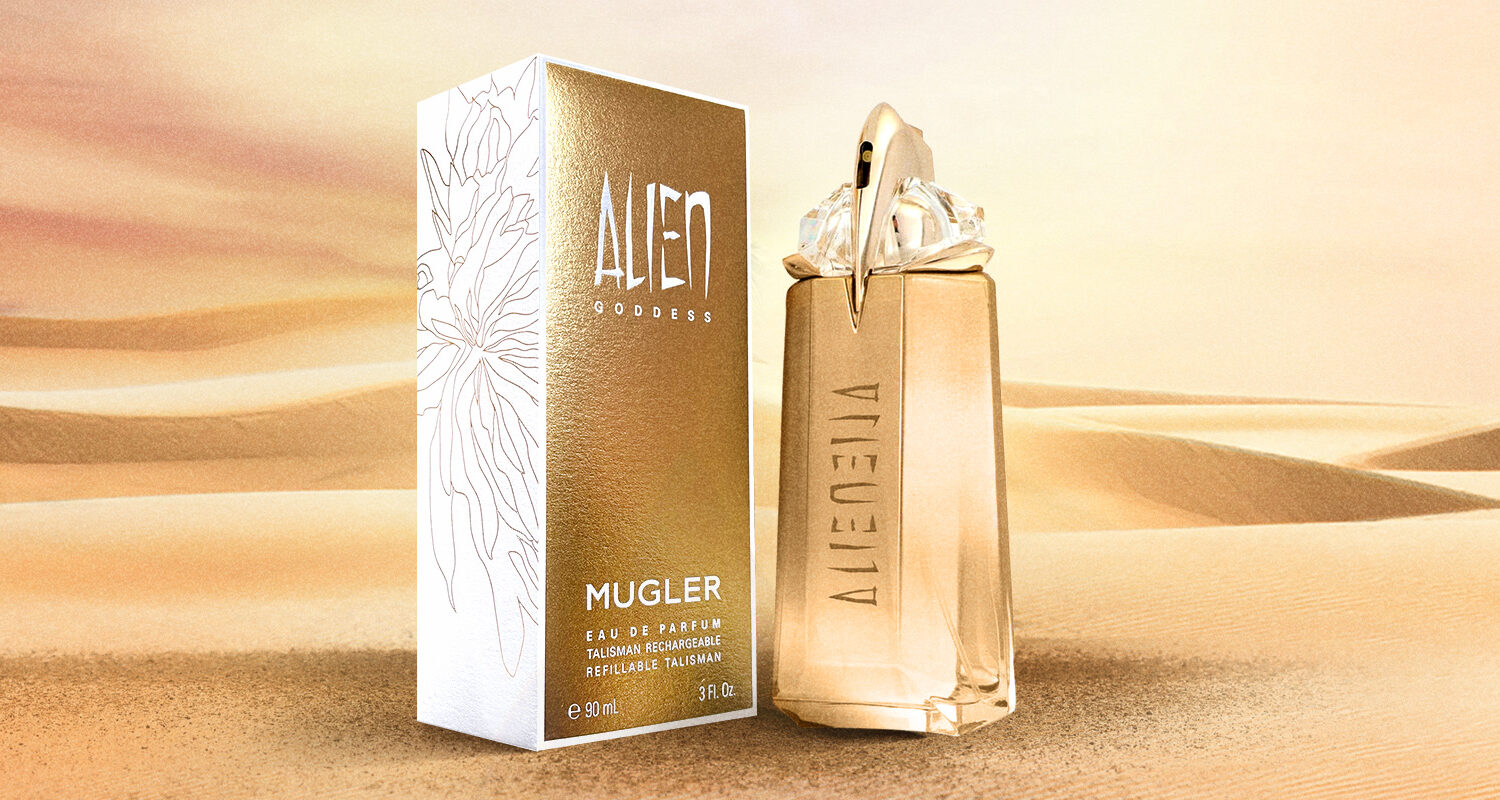

Although cold stamping is not intended to replace hot stamping, it is an alternative and complementary process which has three major advantages: performance, ecology and design.

A “simplified” process

Gilt is directly transferred on the offset machine.

Unlike hot stamping which requires the use of a stamping die, in cold stamping, the foil is transferred to the substrate using an adhesive.

No more need for tools or to set up the substrate on a new machine, everything is done in-line on the new offset machine.

Cold stamping enables overprinting on the gilt.

An adhesive, a vignette, a four-colour process, a spot colour decoration, and the design materialises. Cover white is no longer needed for texts or decorations, we work in reverse, directly on the cardboard.

The technical nature of cold stamping ensures precision, agility, flexibility and speed…

High quality rendering

Overlays are made easier as a result of a registration quality of up to the 100th of a mm: it is no longer necessary to set up the cardboard on another machine, cold lamination is done directly on the offset machine. Precision is a given. From the solid area to the delicate fading, the vignettes are enhanced by unequalled dot fineness.

Adding cover white in several passes is no longer required to regain purity, the reverse in cold gilding can be used as a solid area, for example, to leave room for a four-colour process on the back of the pack, or for incredible finesse for texts, mentions or EANs.

A CSR process

Among its advantages, this technology has ecological merits: it saves time, materials and energy. The cold stamping process reduces waste through precise application.

Used foil rolls are retrieved by the supplier who, after a de-metallisation process, recycles the PET by re-metallising it for a second life.

Producing stamping dies is no longer necessary, and material and energy are therefore saved.

In terms of performance, ecology and design, cold stamping opens new perspectives for high-end packaging. We are hard at work testing the machine from all angles and soon we will provide you with some great demonstrations to help you with your projects.

Wauters and B.Pack teams

Find out more about Heidelberg

Find out more about Vinfoil

Sustainable processing: the Wauters Group’s newest investments

Hot stamping, embossing, varnishing, laminating… These refined finishes are an integral part of luxury packaging.

As experts in hot stamping and high-added-value processing, Wauters has always invested in cutting-edge equipment.

Martell x Wauters: French expertise at its best

As an icon of French luxury and expertise, Maison Martell needs no introduction. Since its foundation 300 years ago, it has made a name for itself as an authority on cognac.

Wauters x Alien Goddess: solar down to the packaging

The solar, divine Alien Goddess, Mugler’s flagship product, has become an essential eau de parfum in the world of perfumery. In keeping with the brand, Wauters has mobilised all its know-how to adorn the box in gold and sunlight.