Spotlight on Spirits (or Packaging for Spirits)

Wauters has always served the Champagne and Cognac market and our industrial facilities and finishing expertise have always been great assets for its specific requirements.

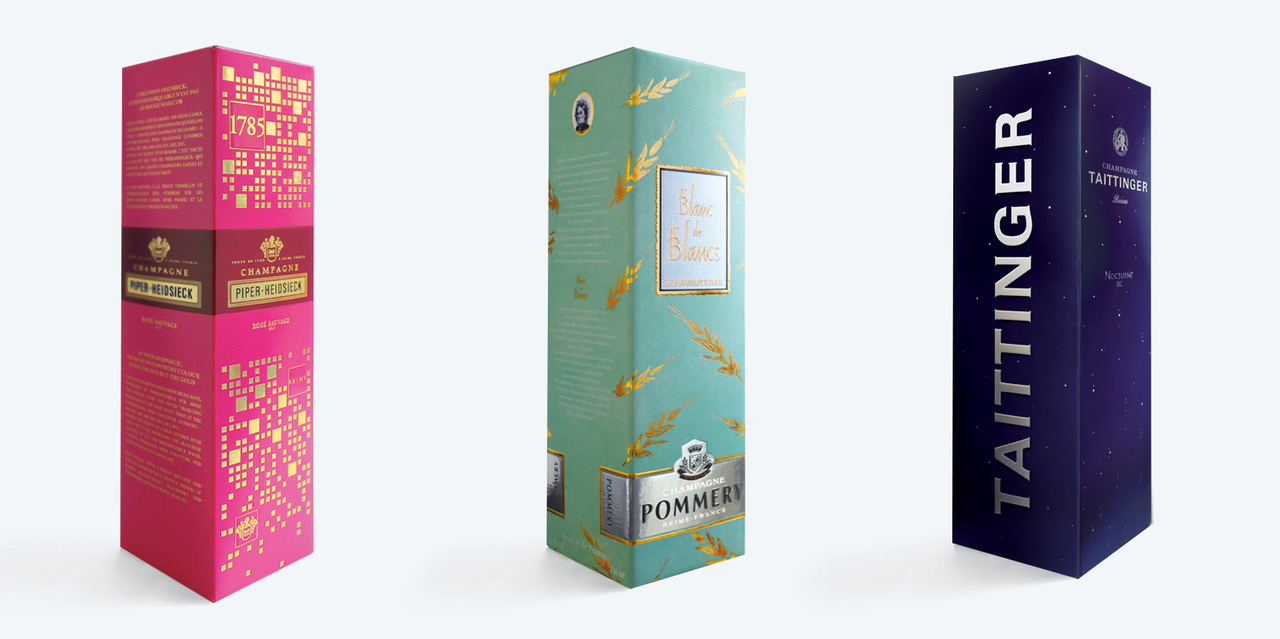

Packaging for spirits follows the standards of luxury perfumes. The culture of excellence resounds through the market’s values of tradition and innovation, authenticity and creativeness. Festive presentations, special blends, XO, Glass packs and canisters now pace the development of the greatest names.

With Martell, Pommery, Taittinger, Pierre Ferrand, Piper Charles Heidsieck, Rémy Martin or Havana Club, Wauters has honed its expertise for more than a century. As it adjusts to the evolving constraints of mechanisation, design engineering is constantly enhanced to integrate an uncompromising cost-time-quality equation. Wauters adapts its solution to the brief: with “mono-material“, “lamination on recycled board” or “lamination on pure cellulose“, premium quality can now make way for luxury. From stiffness to score line quality, many criteria will determine our solution.

The whole array of Wauters gold finishing is available. We recently renewed all our graphic and production lines dedicated to spirits. The large volumes and custom formats of spirits leave no room for approximation and abrasion. Henceforth, offset, film coating, hot stamping, laminating and pasting machines combine speed and quality to optimise costs and results.

At Wauters, we have some great references lined up for 2017. Feel free to visit us.

We look forward to meeting you and seeing you again,

The Wauters and B.Pack teams

A fully renewed production line dedicated to spirits

Offset Machine – Investment 2015

Whether on noble or recycled board, back-to-back or inside and out for laminated board, printing is the key factor of colour and finish.

Wauters’ specific “ink / flexography / varnish” combinations meet the most specific demands all in one run.

No reruns to achieve a perfect register. No production time lost. Endless possibilities of matt/gloss finishing, for contrasts of outstanding precision.

Combined hot stamping and embossing machine – Renewed in 2013

This combined equipment – Station 1: hot stamping – Station 2: embossing – allows these two operations to be carried out in a single operation. By avoiding reruns, the register is perfect, and the quality and speed of application are maximised, for an optimal cost-quality-time ratio.

Hot stamping

Gold hot stamping abounds for spirits, where heritage and tradition are underpinned by attributes of precision. The swift emblem for Martell and the rail track for Piper Heidsieck are two particularly demanding distinctive signs.

Above and beyond the visual result, the quality of hot stamping for spirits is subject to stringent requirements. Abrasion resistance must be excellent, as unlike perfume the packaging is never individually wrapped. It must be able to withstand the rough handling it often suffers.

Graining

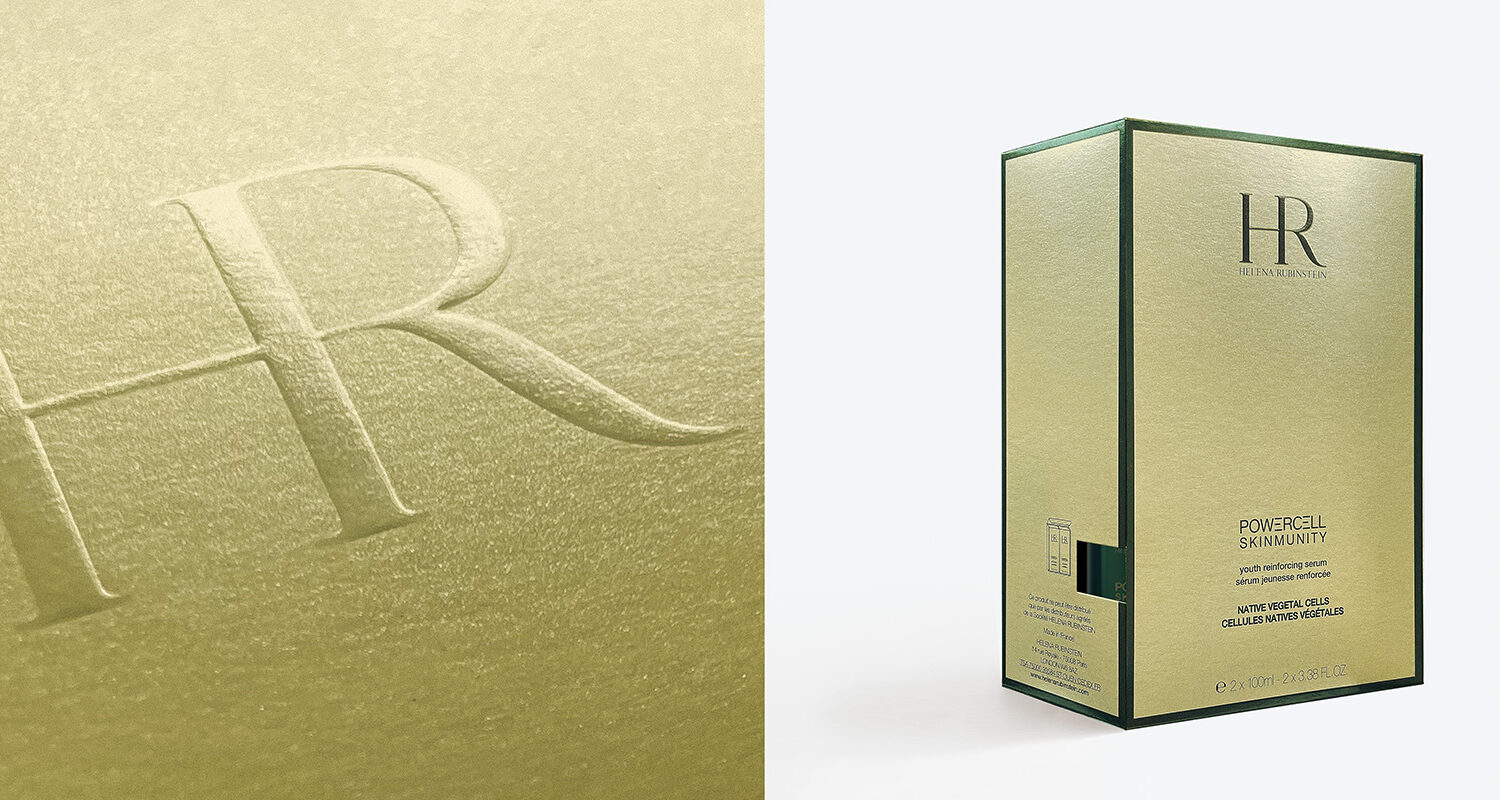

Fine graining and texturing the outer noble paperboard often precede the lamination step. Always keen to rise to demanding technical challenges, Wauters has worked endlessly on grains. The house can propose a vast range of in-house designed effects to support brands and their designs.

Embossing

The thickness of packaging for spirits is a real advantage for embossing. The lamination of 240g for the outer box and 480g for the inner carton (weights usually selected by spirits producers) can achieve a thickness of more than 1mm! Worked in the mass, the raised design is ample and highly visible.

Film coater – Renewed in 2014

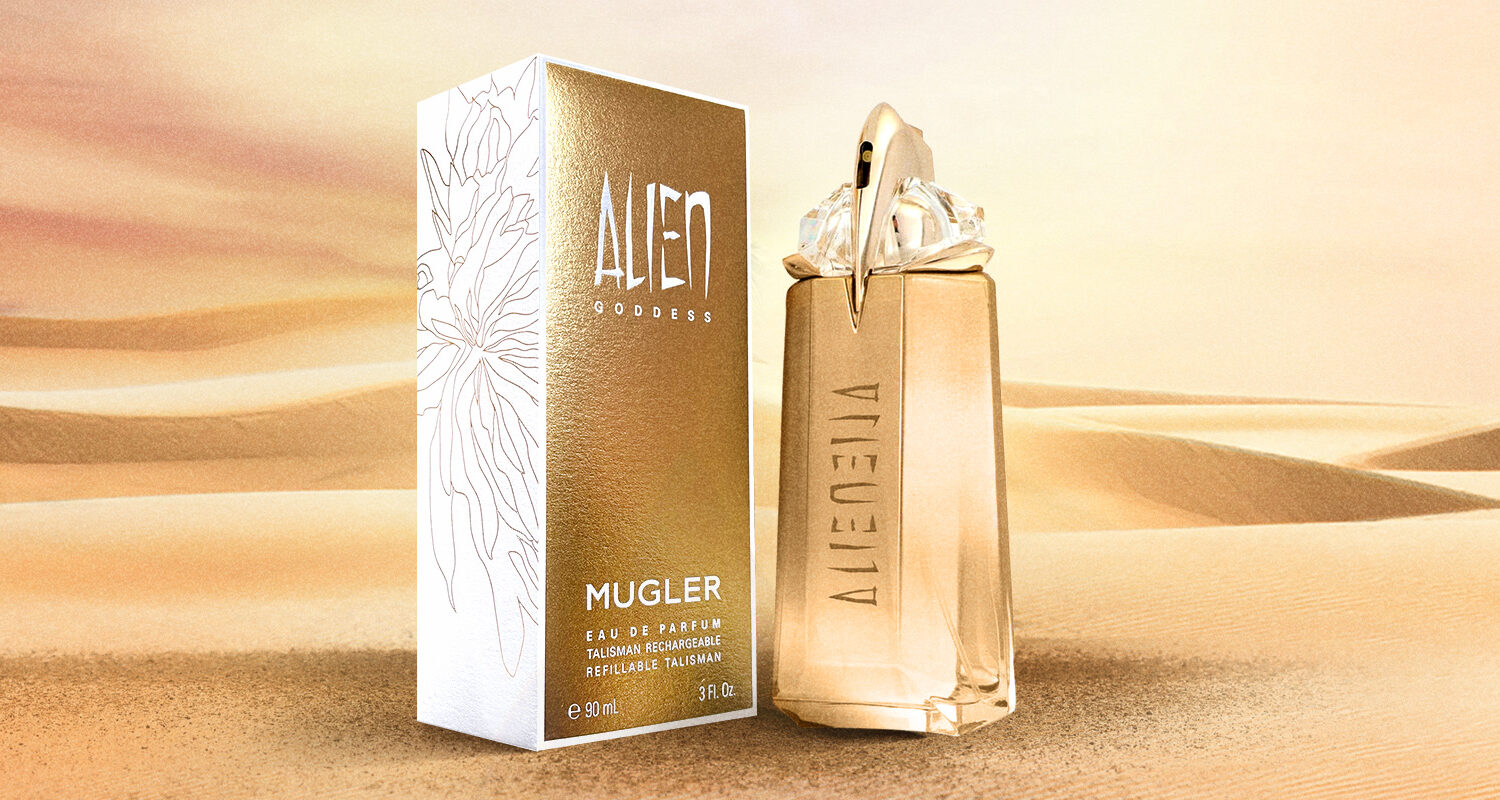

After printing, hot stamping and embossing comes the ultimate film coating step, to add protection and perfection. No quality of varnish can produce the same depth as a glossy or satin film.

Laminator – Renewed in August 2016

Our new laminating machine, specifically designed for large formats, offers both a faster rate and uniform quality for an outstanding performance all round!

The majority of our Premium productions are laminated on carton compact (solid board), which is more regular externally than microflute.

Cutting and stripping machine for spirits – Investment 2014

Cutting and stripping are fully automated processes carried out in complete safety for spirits packaging. Thanks to the high speed, optimised production capacity, the palette of 2,000 sheets is ready for pasting in next to no time.

Pasting machine – Investment 2015

We have reinforced our pasting capacity by adding an extra line.

We now have two lines fully suited to spirits (simple pasting or auto bottom) featuring the latest technologies: these machines are particularly gentle with the boxes and avoid all scratches and scuffing, offering an initial margin to avoid any mark or trace of the belt.

To learn more about our know-how in the production of packaging for spirits : click here

To discover our packaging for spirits : click here

To learn more about our expertise : click here

Sustainable processing: the Wauters Group’s newest investments

Hot stamping, embossing, varnishing, laminating… These refined finishes are an integral part of luxury packaging.

As experts in hot stamping and high-added-value processing, Wauters has always invested in cutting-edge equipment.

Martell x Wauters: French expertise at its best

As an icon of French luxury and expertise, Maison Martell needs no introduction. Since its foundation 300 years ago, it has made a name for itself as an authority on cognac.

Wauters x Alien Goddess: solar down to the packaging

The solar, divine Alien Goddess, Mugler’s flagship product, has become an essential eau de parfum in the world of perfumery. In keeping with the brand, Wauters has mobilised all its know-how to adorn the box in gold and sunlight.