Rémy Martin XO packaging: from eye to palate

“Nose, Palate, Finish”

Spirits reveal their aromas in three stages.

Invented, developed, blended and aged, the flavours and texture unfold to reflect their terroir and the passing of time.

Packaging for an XO particularly follows the highest codes of luxury, demanding precious materials, an aura of tradition and a sensory experience. It is designed to be a subtle reflection of what it contains. We are pleased to present the fruit of our work on the Rémy Martin XO packaging range.

XO, “extra old cognac”, is a tribute to three centuries of union between Grande and Petite Champagne, at the heart of Rémy Martin. For over 30 years, XO has embodied the excellence of this emblematic blend.

Just like a cellar master, always respectful of the materials and experts in their assembly and transformation, we carefully design the end product, step by step, balancing and comparing the options.

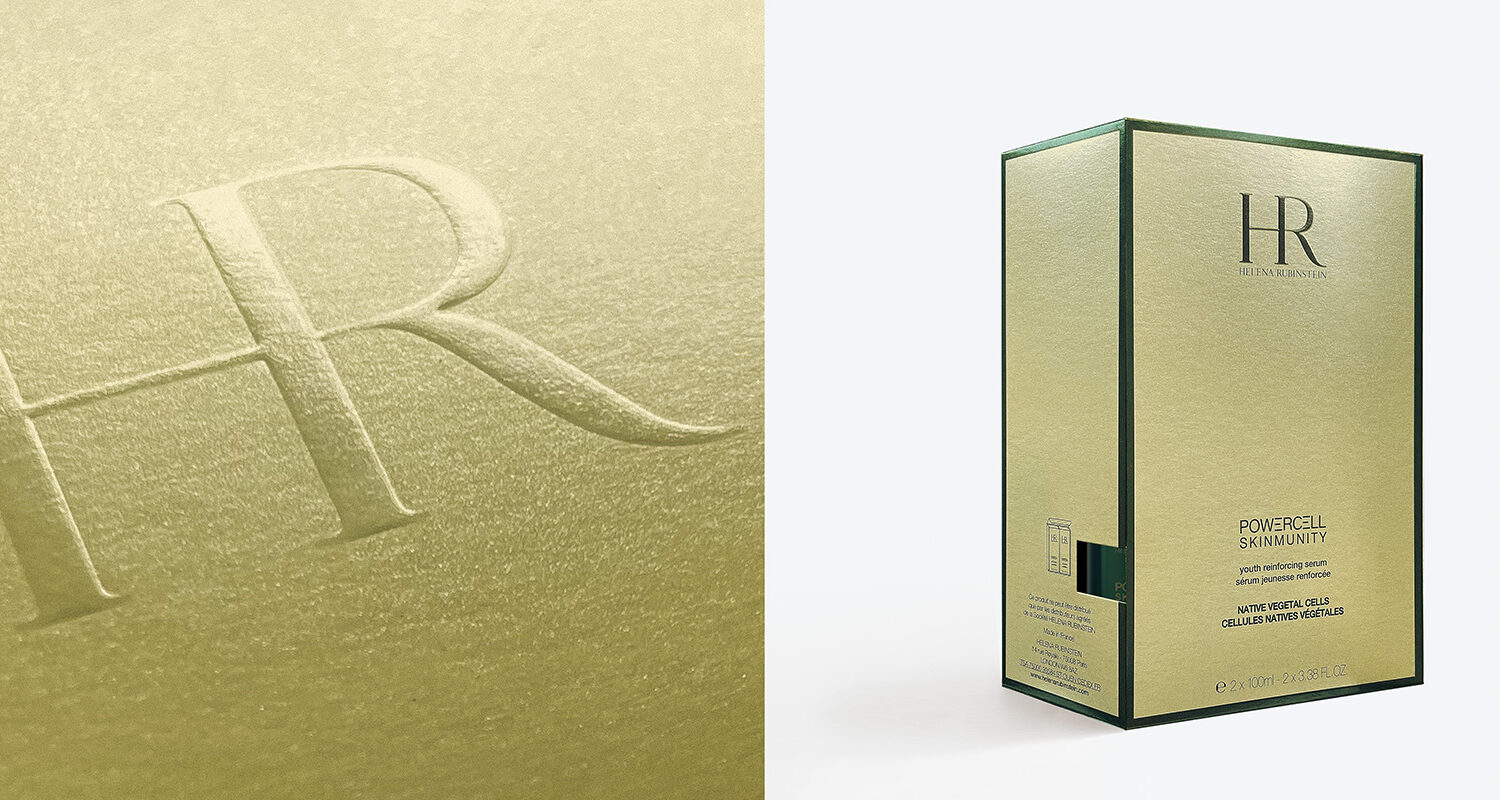

Creating the contrasts, raising and lowering the embossing, revealing the density of the colours, orchestrating the shading, refusing to compromise, aiming for excellence, working meticulously: Wauters applies its expertise in the design and implementation of unexpected technical solutions.

We will let you in on a few trade secrets of this magnificent Rémy Martin XO box.

It all starts with the selection of the outer board. Depending on the size of the box (5cl, 37cl, 5cl, 70cl, 1l and 1.5l), we will choose between 240g or 260g Invercote board. The metallic look is obtained by applying a film of shiny silver polyester. So if you think you spotted a hint of gold, look again. Glossy and matt surfaces play with light, thanks to a skilful addition of varnish. The brown and red offset shades are enhanced, the whole operation taking place in a single run, thanks to our new offset configuration.

Inside, Korsnas Carry board is fully covered with a sold tint enhanced with an ultra-glossy varnish. Each detail counts. From active contribution to stiffness, to score resistance when the box is opened, the back liner of luxury spirits packaging must meet the highest standards.

The exterior-interior assembly is achieved by lamination.

With subtle grooves radiating from the centre, the magic of this box stems from the fineness of the stamping. The challenge lies in accompanying its progression, to achieve a subtle emergence. Beyond the tools chosen, the implementation takes place in the machine. Using a sheet of tissue, we adjust the pressure of the counter plate, rectify any potential roughness, and distribute the forces to control the appearance of the surface.

For the final touch, the product is embossed with the brand and its famous centaur.

Today, the creativity of spirits and the rich expression of brands are featured increasingly on secondary packaging.

Not only a protective case, it is also the first illustration of their (and our) know-how.

Discover our expertise and packaging solutions for wines, champagnes, rums and cognacs, designed to meet and surpass all expectations.

The Wauters and B.Pack Teams

To learn more about our know-how in packaging for spirits: click here

To discover our packaging for spirits: click here

To learn more about our expertise: click here

Sustainable processing: the Wauters Group’s newest investments

Hot stamping, embossing, varnishing, laminating… These refined finishes are an integral part of luxury packaging.

As experts in hot stamping and high-added-value processing, Wauters has always invested in cutting-edge equipment.

Martell x Wauters: French expertise at its best

As an icon of French luxury and expertise, Maison Martell needs no introduction. Since its foundation 300 years ago, it has made a name for itself as an authority on cognac.

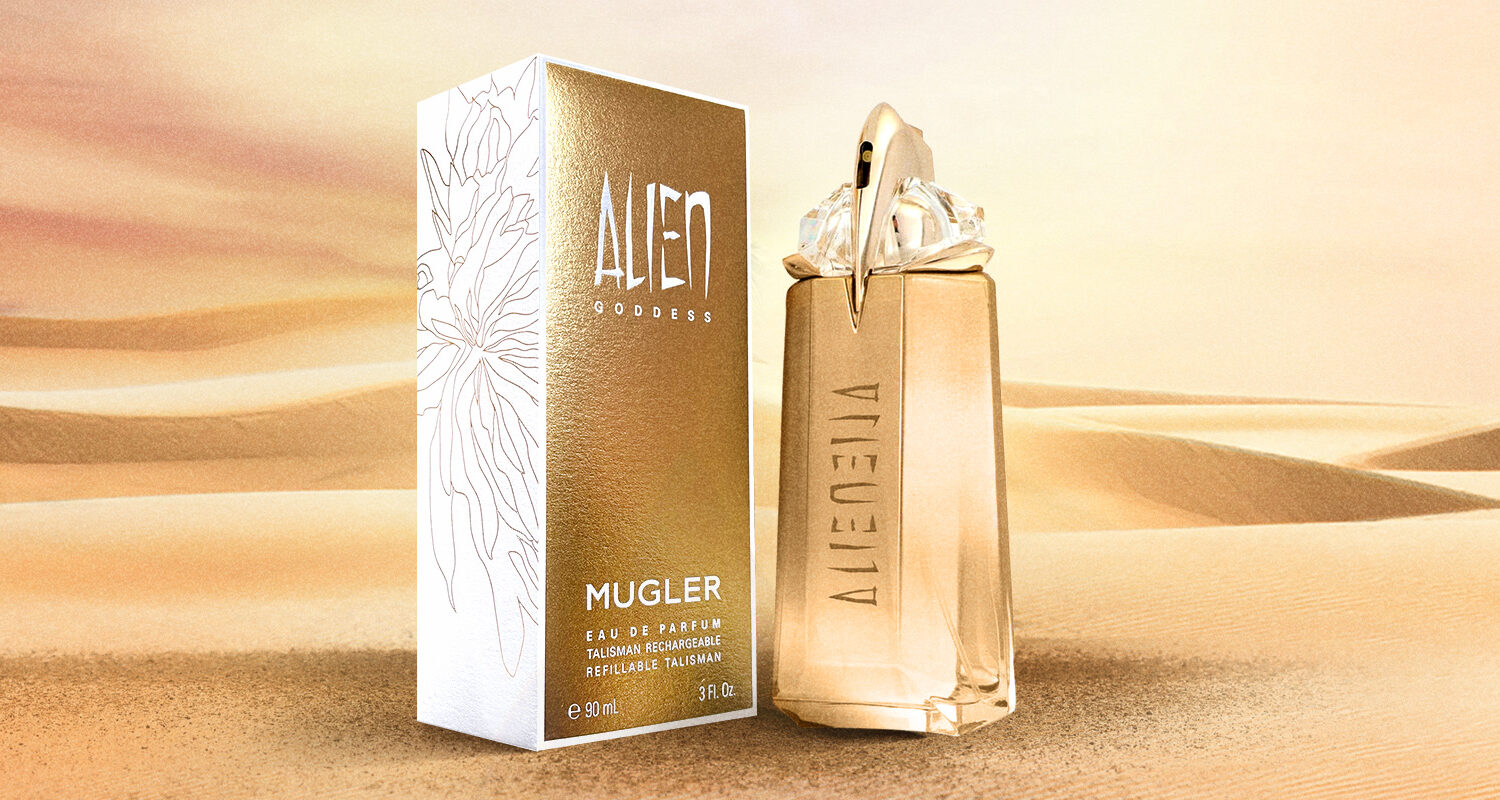

Wauters x Alien Goddess: solar down to the packaging

The solar, divine Alien Goddess, Mugler’s flagship product, has become an essential eau de parfum in the world of perfumery. In keeping with the brand, Wauters has mobilised all its know-how to adorn the box in gold and sunlight.